WelcomeC&M/Components & Machines e.U.

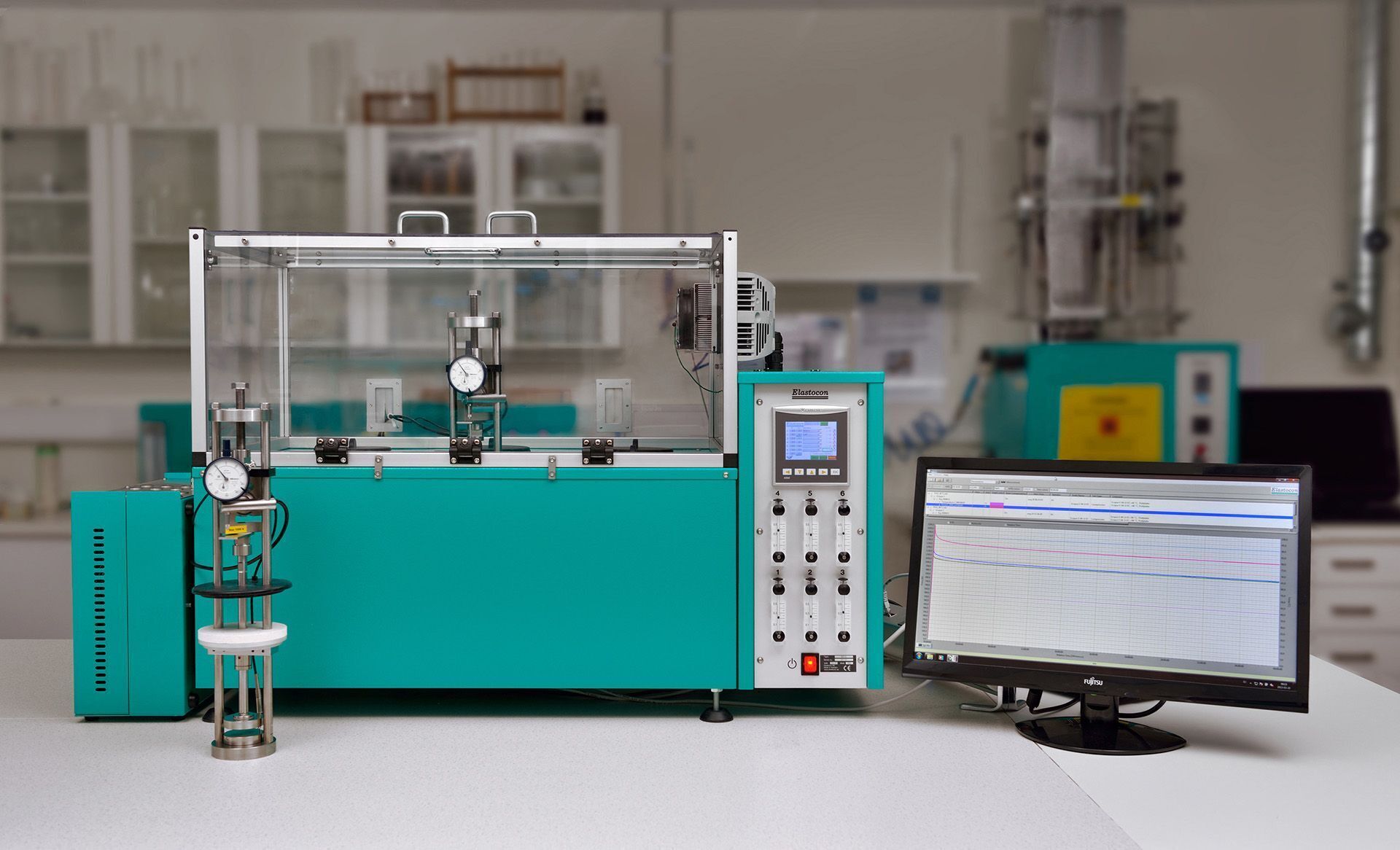

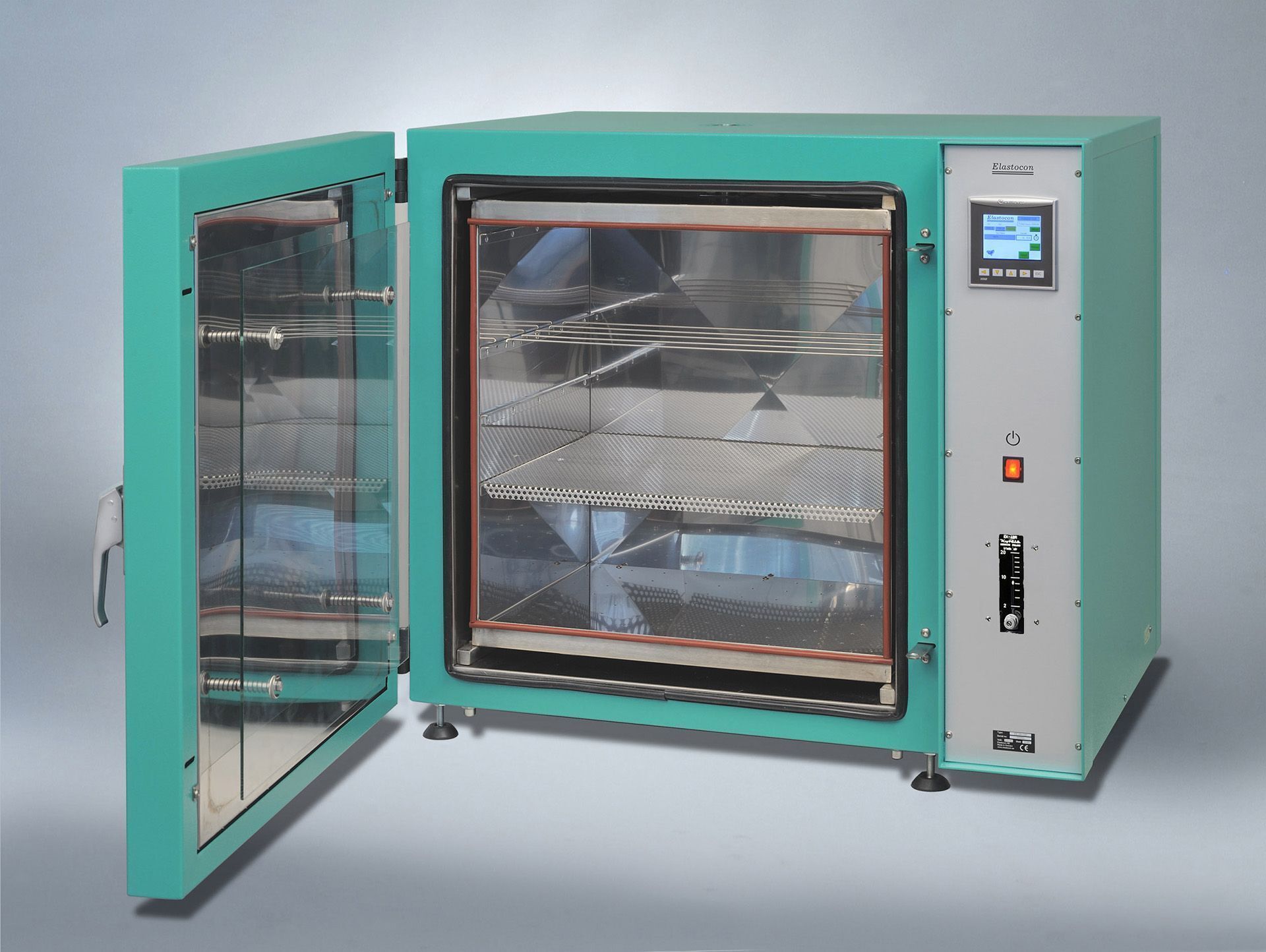

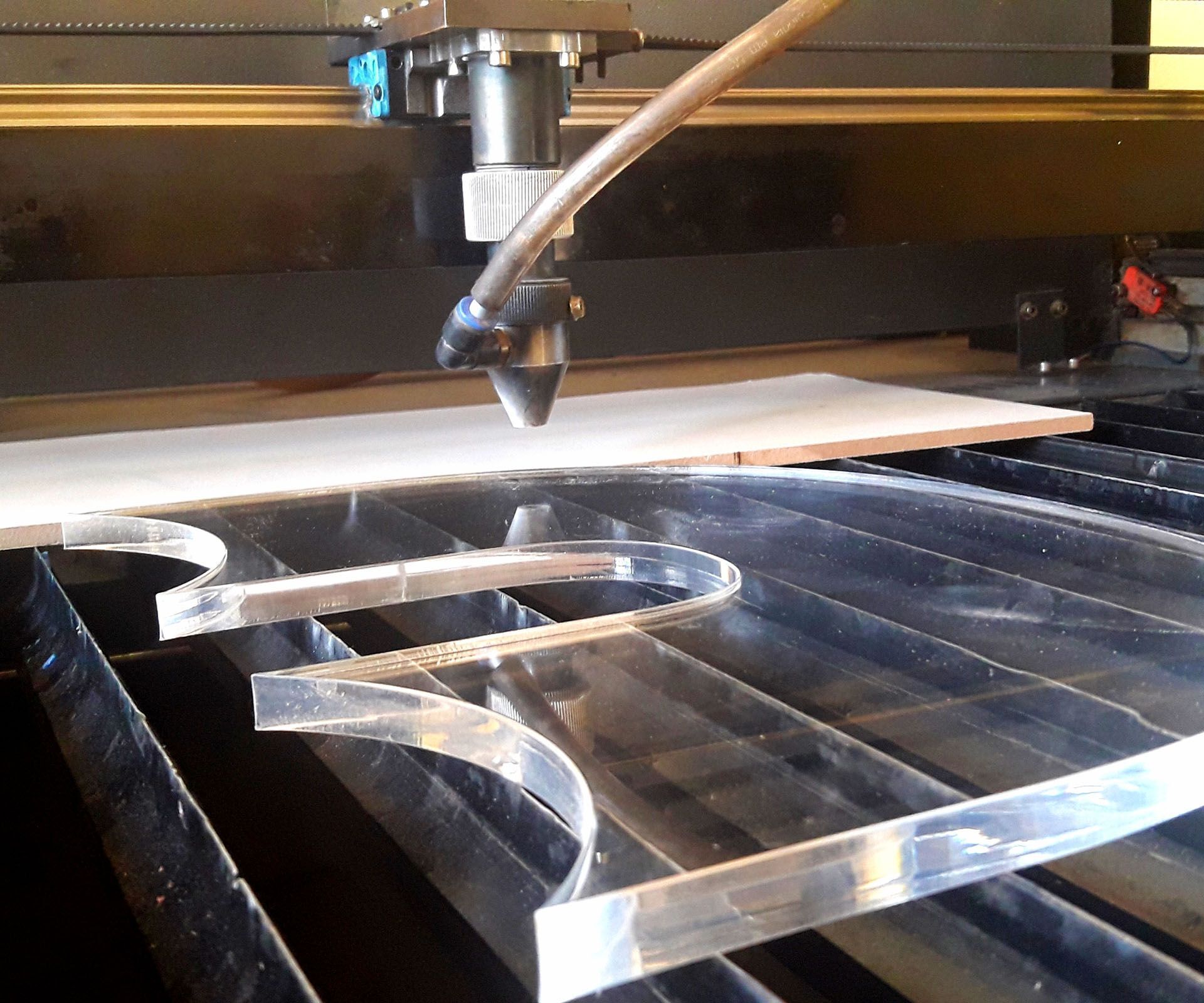

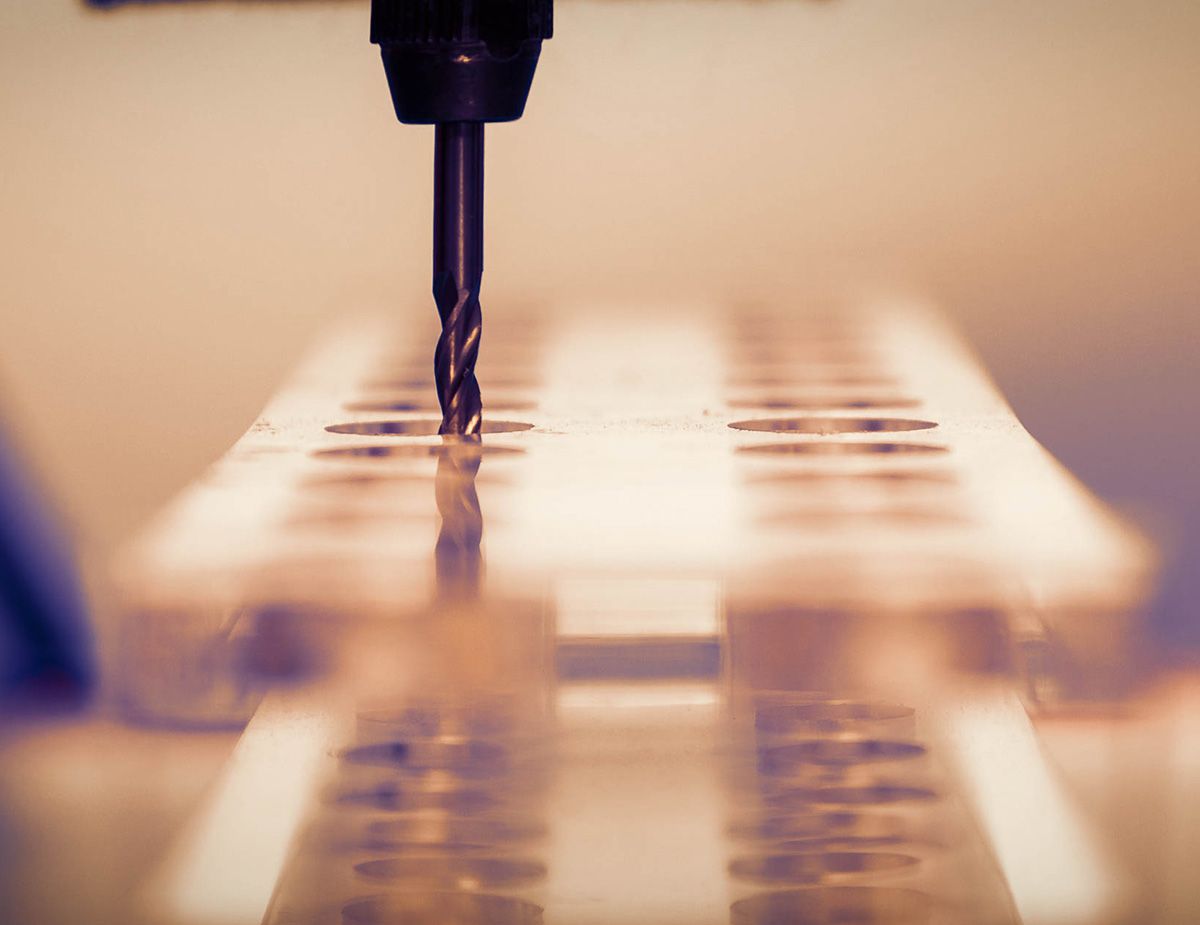

Wholesale for testing technology and plastic welding technology. In our selected range, we offer you the best quality from the respective market leaders.

Our customers can be found in the following industries:

- Chemistry

- Automotive Industry

- cosmetics industry

- food industry

- Aerospace Laboratories

- Institutes

- medical technology

- Optics

- Pharmacy

- rubber and plastics industry

Got interested?

Feel free to contact us!

We have been active since 2005 and have acquired a great deal of know-how in our field to this day, which benefits our customers through the best advice and

dedicated customer care.