TINIUS OLSEN Materialprüfgeräte

Benchtop Testers

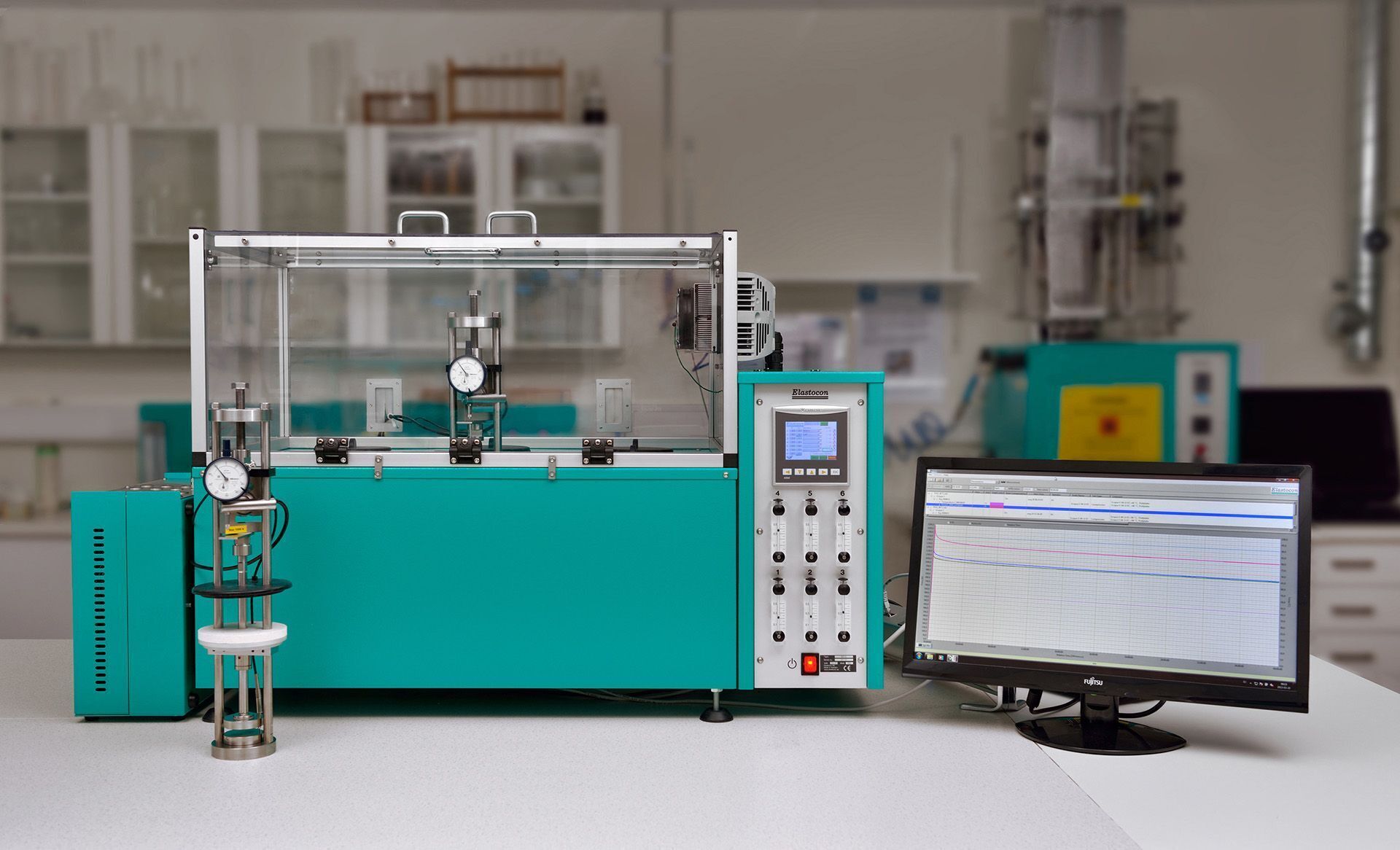

The ST Series of electromechanical testing machines from Tinius Olsen is designed to test a wide range of materials including, but not limited to: plastics, films, paper, packaging materials, filter material, adhesives, foils, food, toys, medical devices and components, in tension, compression, flexure, shear and peel. All ST series machines can be used with selection of handheld interfaces or a virtual machine interface running on a connected PC. Powerful data analysis and machine control software (our Horizon Materials Testing software) can be added to your system to provide a library of standardized test routines, generate a complete graphical result of your test, and perform sophisticated powerful analyses on the test data to produce the test report you need.

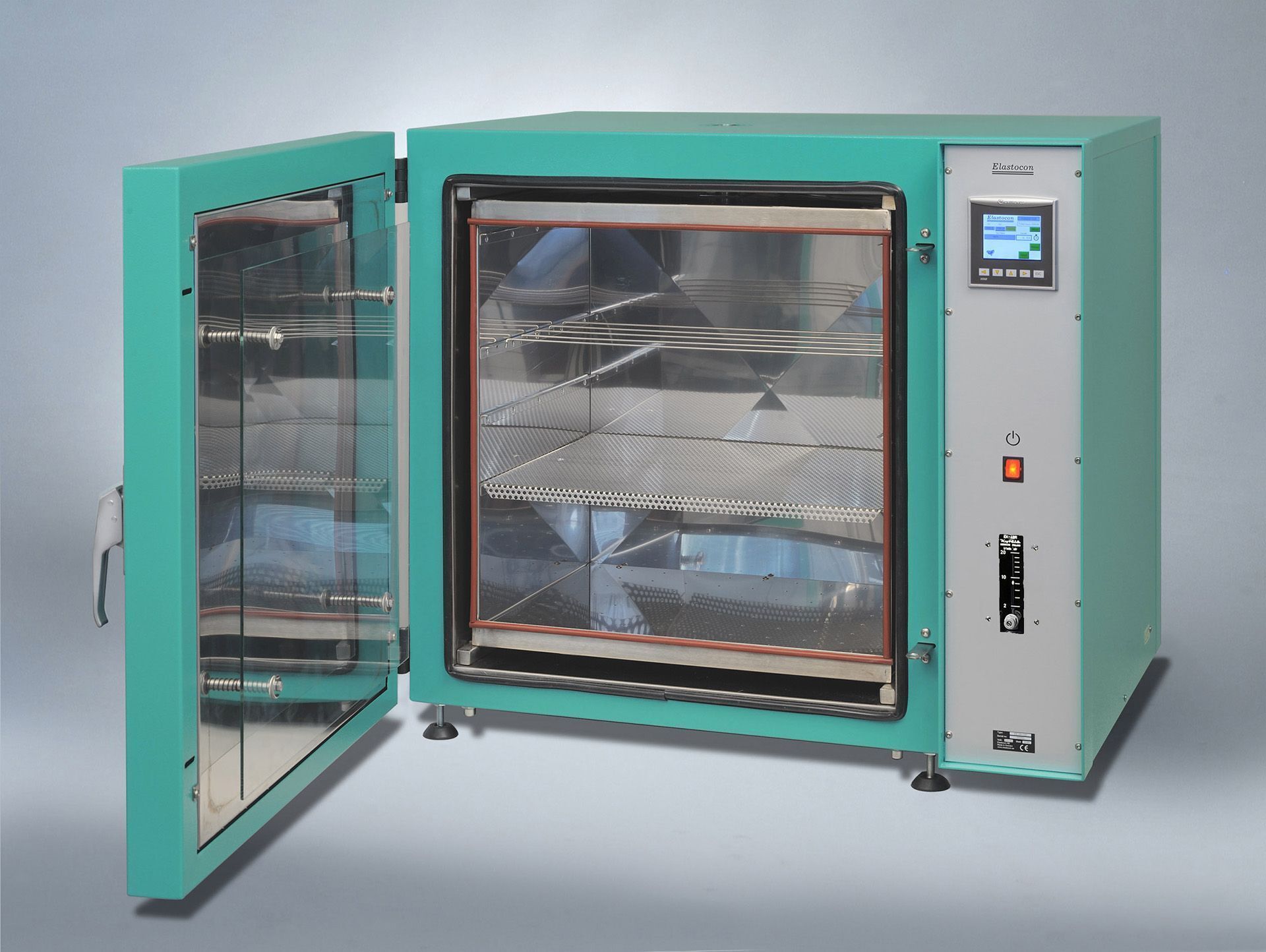

A comprehensive selection of self-identifying load cells, grips and fixtures hold the simplest to most complex specimen profiles, strain measurement instruments employ different technologies, temperature chambers and more can be used in conjunction with these test frames and Horizon software to ensure you have one of the best, most accurate repeatable, flexible and easy-to-use systems on the market today.

Two Colomn / Universal Testing Machines (UTM)

The Tinius Olsen benchtop range of ST models features both single and dual column frames.

The single column models have frame capacities of 1kN (100kgf/200lbf) and 5kN (500kgf/1,100lbf), while dual column models are available in capacities of 10kN (1,000kgf/2,200lbf), 25kN (2,500kgf/5,000lbf) and 50kN (5,000kgf/11,000lbf), and are designed to test a vast range of materials and finished products for strength properties in tension, compression, flexure, shear, tear and peel.

They provide the ultimate in durability, speed, accuracy and convenience and feature high precision, interchangeable strain gage load cells for capturing applied load data. This design allows rapid change of machine capacity from as little as 0.2% of the capacity of the smallest load cell (exception in 5N&10N) to the maximum frame capacity in a very simple process.

The construction of the machine frame, leadscrews and drive system make them unique. Even at full capacity, these frames have excellent rigidity with negligible frame deflection.

Melt Flow Indexer

Tinius Olsen is proud to introduce the latest addition to its polymer testing line, the MP1200 Melt Flow Tester/ Extrusion Plastometer. The MP1200 features the latest in melt flow measurement technology and allows operators to quickly and easily set up and perform melt flow tests, according to ASTM D1238, ISO 1133-1 & 2, and other international and industrial specifications.

The MP1200 is available in two versions: a manual version (Model MP1200), and a motorised version (Model MP1200M). The manual MP1200 comes with everything you need (except weights and laboratory balance) to perform an ASTM D1238 Procedure A (manual cut) gravimetric melt flow rate (MFR). Test loads are applied manually. The MP1200 can be upgraded with optional features, including ISO 1133 tools and an encoder-based programmable piston displacement transducer (or PPDT for short), for testing according to Procedures B & C (ASTM D1238) or for volume measurement tests (melt volume rate or MVR) and melt density calculations. Also available are manual and automatic specimen cutting tool attachments, which can be used with some materials to reduce human involvement with the machine during the test and increase accuracy and repeatability.

The MP1200M is equipped with a motorised weight lifting and lowering device (WLD) that further automates the testing procedure. The WLD safely and automatically applies test weights to the piston at a user selected time interval during the test. It is also available with the PPDT and cutter options, as well as the Flow Rate Ratio (FRR) attachment for ASTM D1238 Procedure D for polyethylene and the Purge and Purge/Clean options. Both versions feature a redesigned furnace that uses a three-zone band heater for unsurpassed temperature control (+/- 0.1°C from set point)along the entire testing area of the bore, meeting the new requirements specified in ISO 1133-2. The furnace also features a quick action die release for easy removal of the die for cleaning after a test.

The MP1200 features a userfriendly color touch-screen LCD display. Operators can configure the options available for the machine and program user settings (language, units, alarms, etc). Individual test protocols can be set and stored for rapid recall when needed. When programming tests, operators have the option of selecting which sample identifiers they wish to use from a preloaded list or can make their own identifier. They can also select which test results they wish to report. Test results are displayed automatically at the end of the test and can be saved or printed out to a printer connected to the MP1200’s USB port. For more sophisticated data collection, the MP1200 works with Tinius Olsen’s Horizon software, which can store an unlimited amount of test settings and test results. Test reports and SPC control charts can also be generated.

Low Energy Impact Testers

Low Energy Impact Testers

Tinius Olsen manufactures a range of different pendulum impact testers that can be easily changed from a Charpy configuration to an Izod configuration. These testers come in a couple of capacities and are designed primarily for either plastics or metals impact testing.

All testing hardware is fully complemented by Tinius Olsen developed software that turns your hardware into a sophisticated quality analysis system. Be sure to examine the software products to determine which package is right for your application.

High Force Electromechanical Testers

High Force Electromechanical Materials Testing Machines

These rugged electromechanical testing machines are designed to test metals, composites, rigid reinforced plastics, webbing etc. in tension, compression, flexure, shear, tear and peel. These machines feature high precision interchangeable loadcells, superior pre-loaded ballscrews and powerful drive systems that mean they can easily tackle the most challenging of applications.

Load frame capacities are 100kN (22,500 lbf), 150kN (33,750 lbf), 200kN (45,000 lbf) and 300kN (67,500 lbf).

All testing hardware is fully complemented by Tinius Olsen developed software that turns your hardware into a sophisticated quality analysis system. Be sure to examine our software products section to determine which package is right for your application.

Hydraulic Testers

Hydraulic Testers

Static Hydraulic Materials Testing Machines

Super "L" Testing Machines are rugged tension and compression hydraulic machines proven in thousands of demanding applications worldwide. Available with digital readout ...and optional servo and computer control systems. Maximum frame capacities from 150kN (30,000lbf, 15,000kg).

All testing hardware is fully complemented by Tinius Olsen developed software that turns your hardware into a sophisticated quality analysis system. Be sure to examine the software products to determine which package is right for your application.

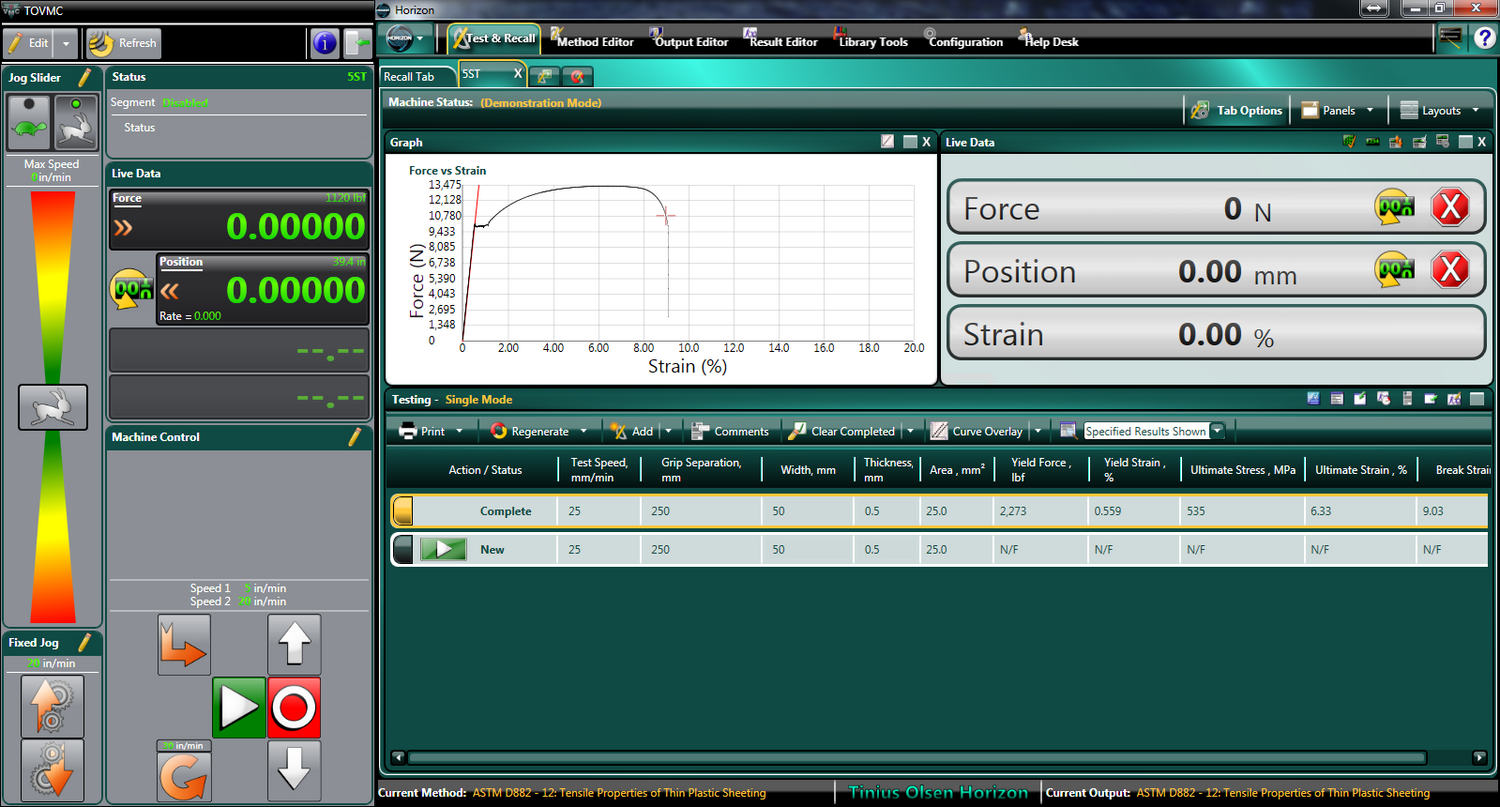

HORIZON Test Software for all of our UTM's

Tinius Olsen is proud to introduce the next evolution of testing software with our Horizon package. As part of our development process, we have taken the best features of our existing software

offerings, including Test Navigator, QMat, and EP600 software, added a host of report writing and data manipulation capabilities and, in the process, created a new, unparalleled testing platform

that will make easy work of your materials testing programs, whether they’re designed for the demanding rigors of R&D or the charting and analysis functions of QC testing. One of the first features you see within the Horizon software is its use of the most current Windows environments. These familiar formats make it easy to use and learn, especially since the same familiar functionality is maintained throughout the program.

Hardness testing metals

Tinius Olsen is a manufactur of different hardness testing instruments for all conventional hardness testing proceedings like: BRINELL HB / ROCKWELL HR / ROCKWELL SUPERFICAL (HR Scala) / VICKERS HV / Micro VICKERS HV / KNOOP HK, etc..

For a attractive price.