Ageing Testers Cell Ageing – Ovens

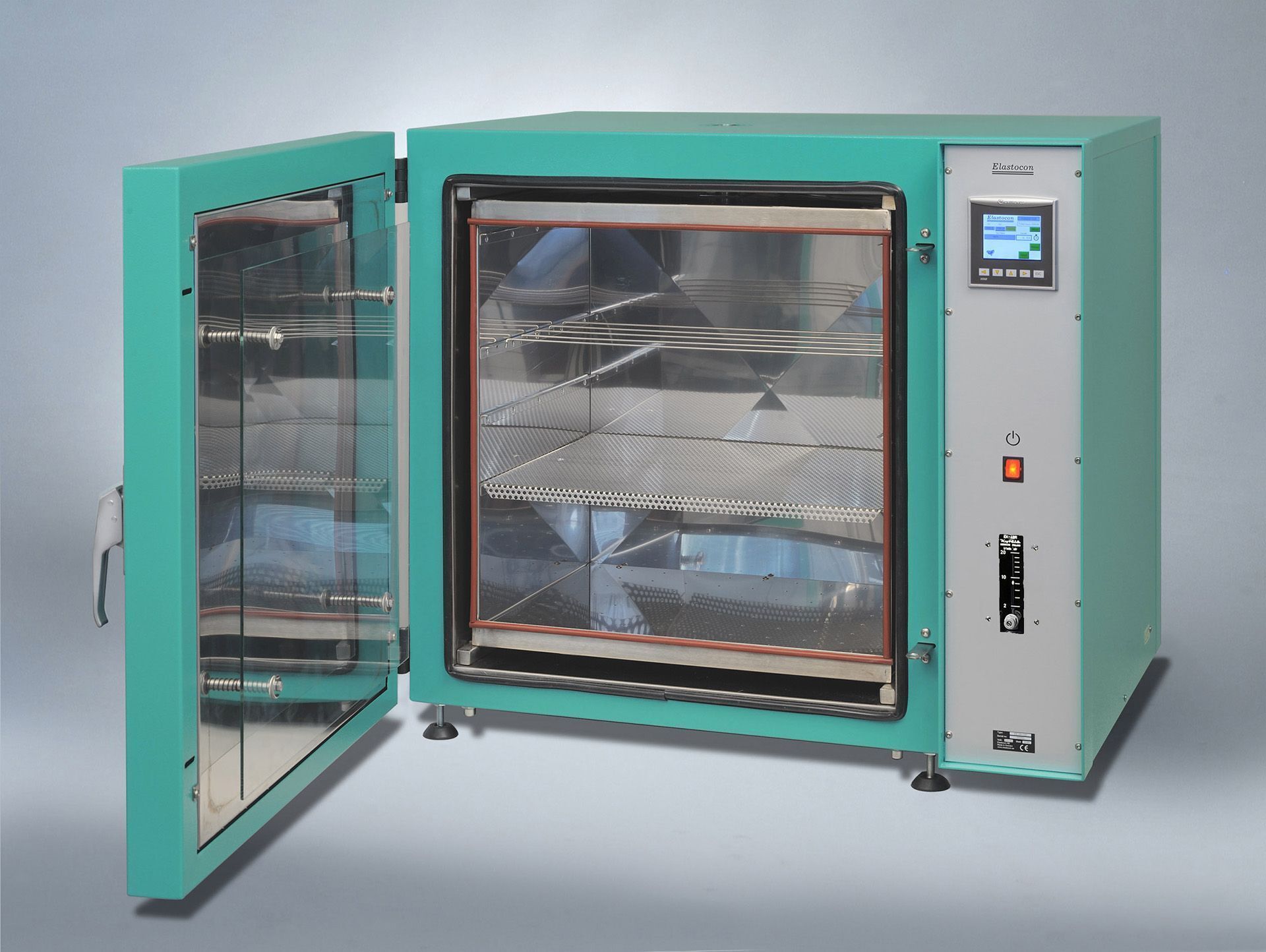

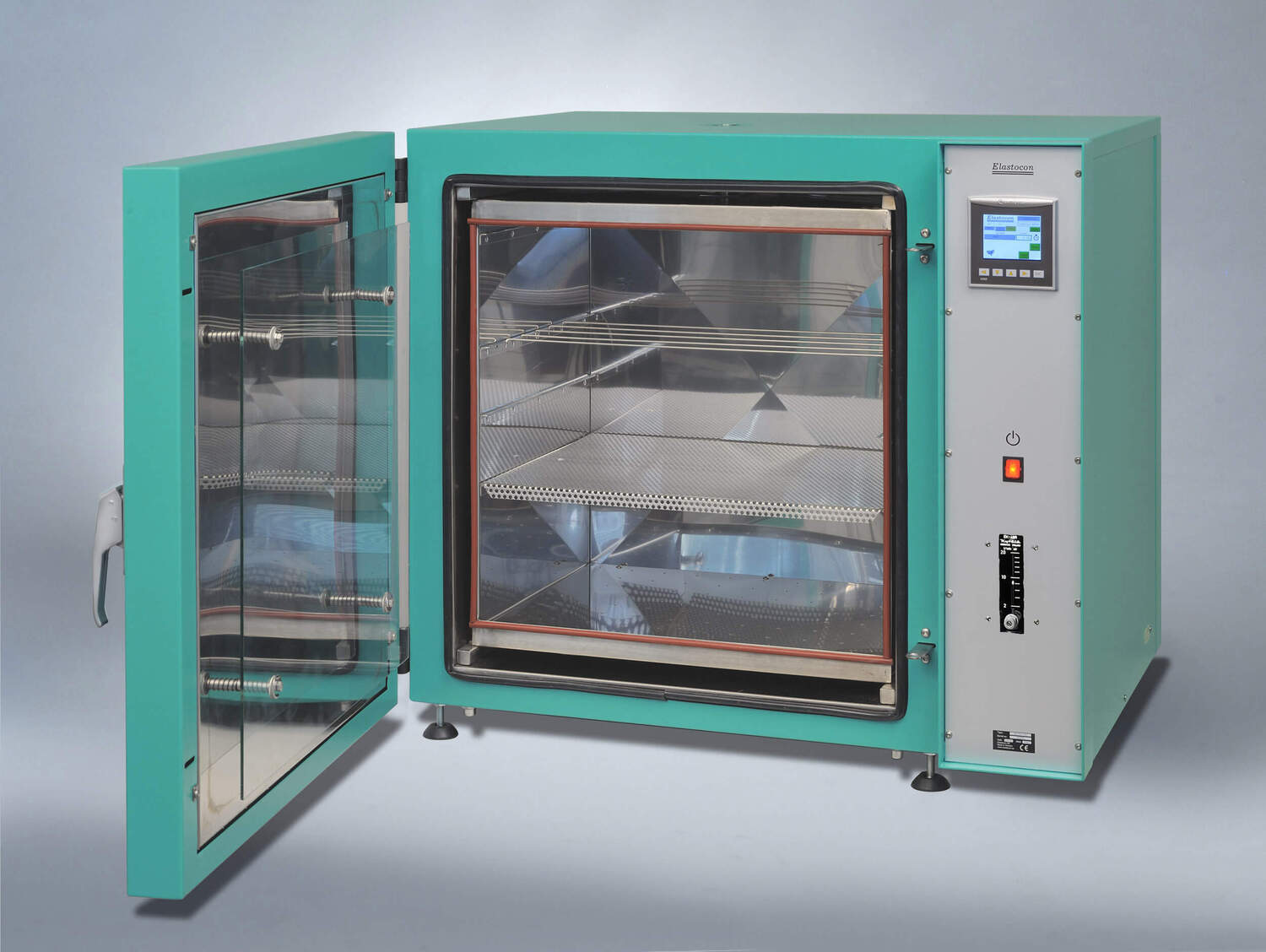

Cabinet Oven EB 04-II

The EB 04-II cabinet oven has low air speed and a flow meter that can be set between 3 to 20 changes per hour, which meets the requirements in ISO 188 method A.

EB 04-II is a cabinet ageing oven for precision ageing of rubber and plastics under controlled conditions. The oven is supplied in two sizes, with 60 or 120 litres useful volume. The settings are done on the PLC colour touch screen.

The air supply for EB 04-II requires external air. Elastocon offers a silent air compressor, EA 01, if compressed air is missing.

Elastocon’s cabinet ageing ovens have excellent temperature stability and distribution achieved by using an inner chamber with a controlled air flow. The temperature accuracy is very important for heat ageing tests, as a 1 °C error in temperature corresponds to around 10 % error in test time.

Two temperature sensors are used, one for temperature control and one for measuring the temperature close to the samples. This sensor can also be connected to a logging software.

These ovens are ideal for ageing finished products and large test pieces which are unsuitable for cell ovens. Both shelves and rods are supplied with these ovens for accommodating most types of samples.

Click images to enlarge.

Note: For the best performance of the instrument, we recommend a placement in an environment with a stable temperature between +10 to +30 °C.

Standards

The oven performs well inside the apparatus requirements in ISO 188 method A, IEC 60811-1-2, IEC 60216-4-1 and other equivalent standards.

Temperature range

- +40 °C to +200 °C (EB 04-II)

- +40 °C to +300 °C (EB 04-IIHT)

Useful volume

- 60 or 120 litres

Cabinet Oven EB 12-II

The EB 12-II cabinet oven has high air speed with laminar flow from bottom to top, and a factory set throttle to give a fixed air exchange rate of 7 or 14 changes per hour, which meets the requirements in ISO 188 method B.

Cabinet Oven EB 26HT

The EB 26 ageing cabinet has high air speed and a fixed air exchange rate of 7 or 14 changes per hour, which meets the requirements in ISO 188 method B. This oven also has a carousel for simple and fast mounting of the samples. The carousel – which rotates during ageing – has room for up to 36 samples.

Cabinet Oven EB 27

The EB 27 cabinet oven has 2 flow meters to cover the exchange rates between 3 to 200 changes per hour, but still with low air speed inside the chamber. This cabinet oven meets the requirements in ISO 188 method A, IEC 60811-1-2, IEC 60216-4-1, ASTM D5423 type 1 and 2, ASTM D573 and ASTM E145 type IIA.

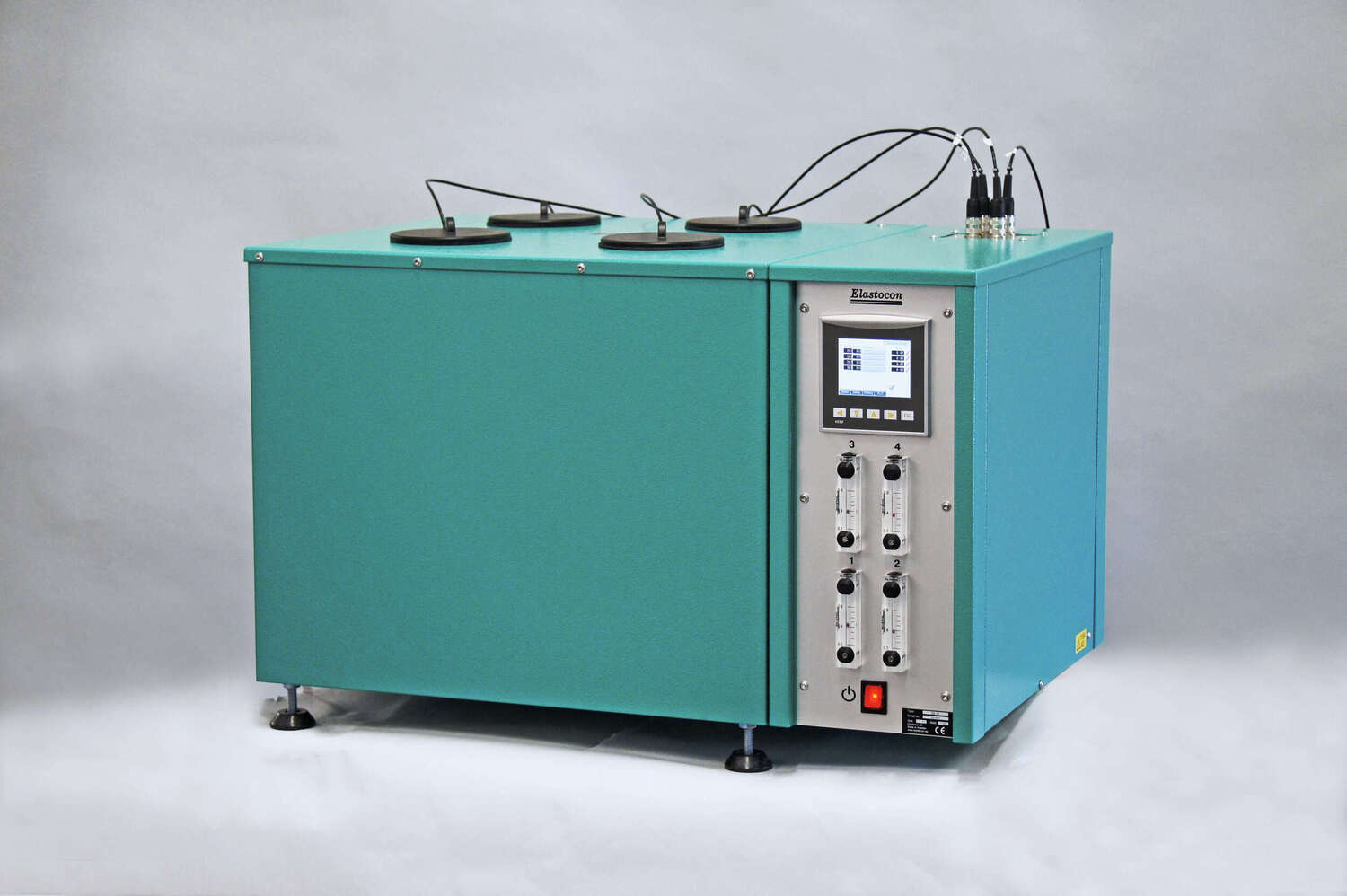

Cell oven EB 01-II

Elastocon offers a EB 01-II cell oven for immediate delivery. The EB 01-II cell oven is equipped with 4 cells, with one temperature for all cells. Each cell has individual control of the air exchange rate and has room for 24 test pieces.

Cell oven EB 19

The EB 19 cell oven is equipped with 4 cells, each with individual temperature. Each cell has individual control of the air exchange rate, and has room for 24 test pieces.

Cell oven EB 20

The EB 20 cell oven is equipped with 6 cells, each with individual temperature. Each cell has individual control of the air exchange rate, and has room for 24 test pieces.

Cell oven EB 21

The EB 21 cell ovenfor relaxation tests has 4 cells with individual temperatures and individual control of the air exchange rate for each cell.

Cell oven EB 21 LTHTP

The EB 21 LTHTP cell oven for relaxation tests of rubber has 4 cells with individual control of temperatures and air exchange rate. EB 21 LTHTP can be programmed for temperature cycling between approximately +20 °C to +300 °C.

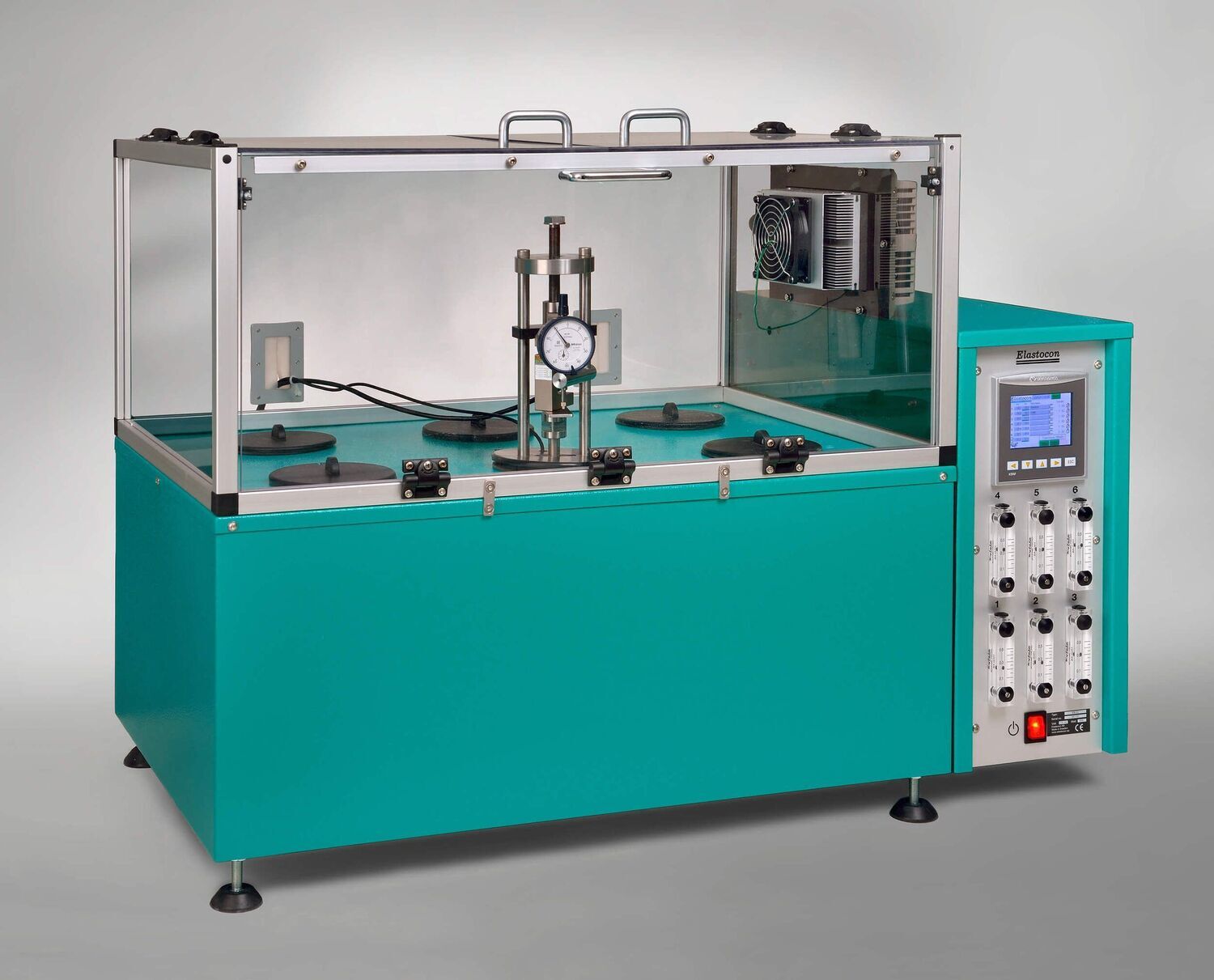

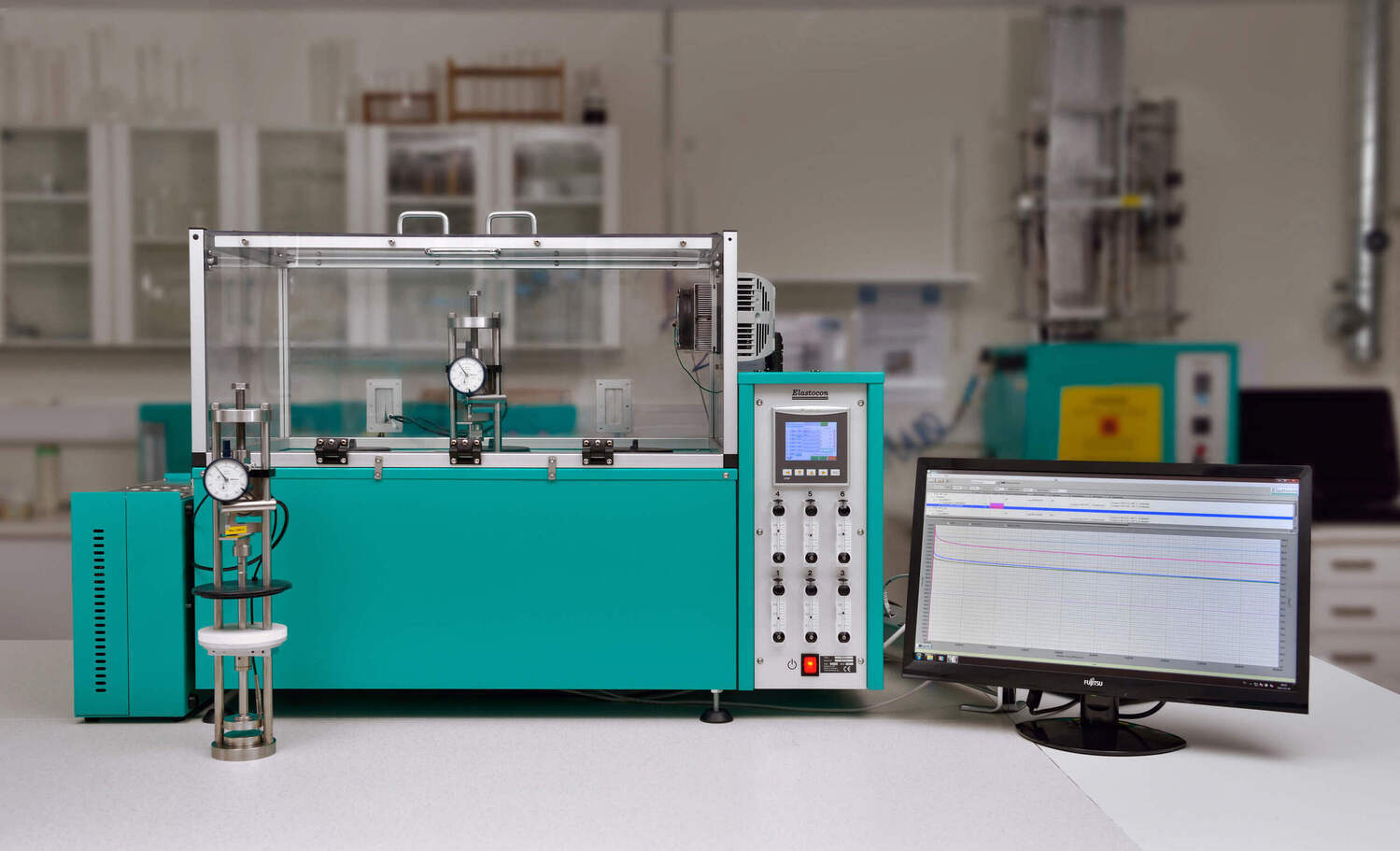

Cell oven EB 22

The EB 22 cell ovenfor stress relaxation has 6 cells with individual temperatures and individual control of the air exchange rate for each cell.

Cell oven EB 36

The EB 36 cell oven has a stirrer that stirs the air in the cells with about 60 rpm and meets the standard AS/NZS 1660.2.3:1998.

Cell oven EB 17

The EB 17 cell oven for relaxation tests with 6 cells with the same temperature and cycling from -70 °C up to +245 °C.

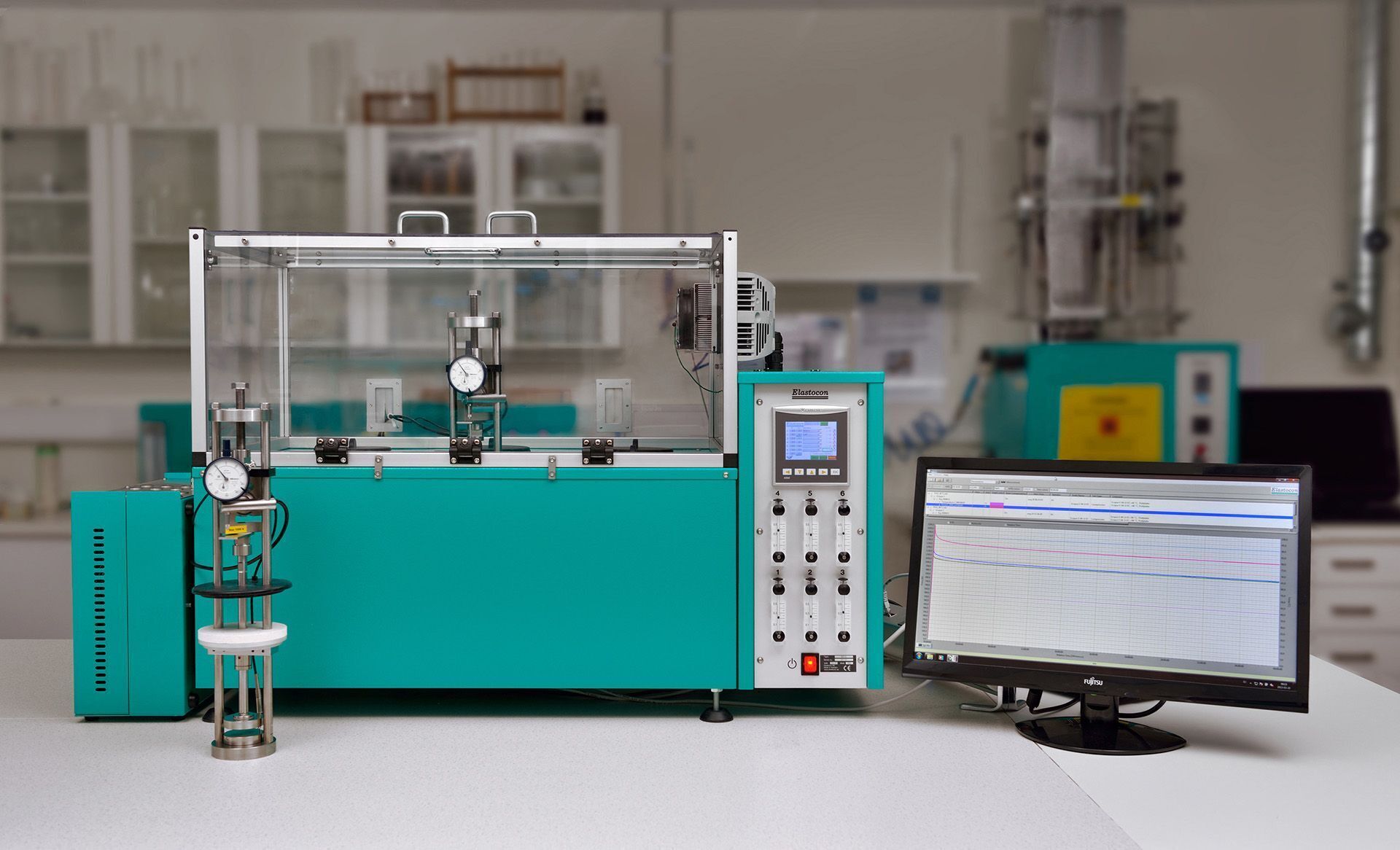

Stress Relaxation Test System

Stress relaxation test system for continuous measurement of rubber in either compression or tension. Meets the requirements in ISO 3384, ISO 6914 and ASTM D6147.

Combined low temperature testers

The TR Tester, Gehman Tester and Brittleness Tester can be combined using the same base unit and a rig changing system.

Fogging Tester, EB 03C

The EB 03C Fogging Tester is an equipment for determination of windscreen fogging in vehicles according to ISO 6452 and SAE J1756.

Gehman Tester, ET 02-II

Gehman Tester, ET 02-II, for determination of the relative stiffness characteristics of vulcanized or thermoplastic rubbers, also called the Gehman procedure. The test is done according to ISO 1432, ASTM D1053, or equivalent standards.

Automatic Relaxation and Creep Tester, EB 18‑II‑3

With the Relaxation and Creep Tester, EB 18‑II‑3, tests can be carried out automatically.